Availability and quality are based on FlowControl

To achieve reproducible, outstanding folding quality and a consistent workflow the CFM has a permanent secret - we call it FlowControl.

FlowControl is the combination of many of the CFM's technical key features, all of which are used for a single reason - to ensure the best folding results without interruption through permanent mechanical control of the article.

Precise article handling

All cross fold stations are foreseen with a mechanical folding blade and reverse belt-principle to always ensure an accurate and safe folding result.

Secure article guidance

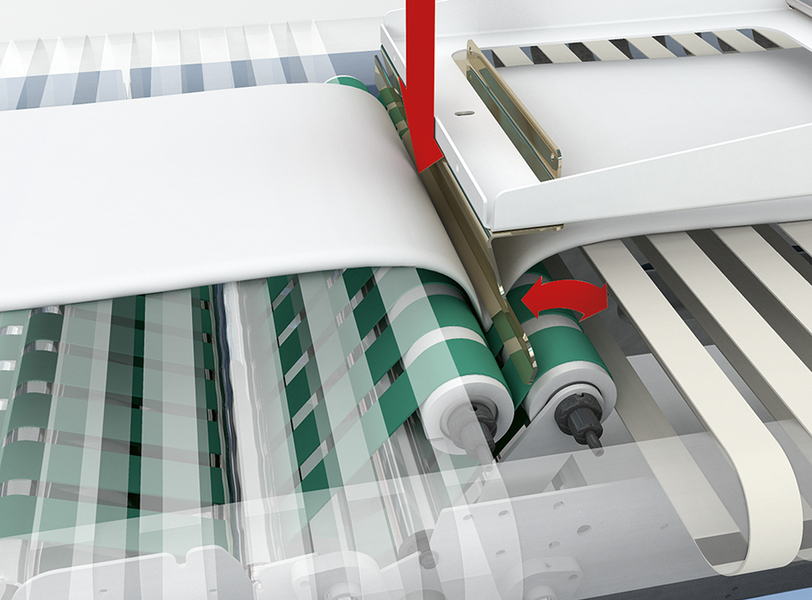

Throughout the folding process the Kannegiesser roller-belt-principle always ensures an automatic thickness adpation without the need of any mechanical or pneumatic device.

Complete article control

High folding accuracy is guaranteed due to measuring wheels. In combination with photocells they always ensure the measuring of the correct item length. Unaligned items coming out of the ironer will be detected by photocells for an automatic reject before the item enters the cross fold section - this way avoiding any jams.

Perfect folding results

The air blast folding principle provides exact folding results for different article ranges applying high process speed and the outcome supports excellent folding and stacking quality.

Technical Data

| Working width | 3,000-4,200 mm |

| Performance |

|