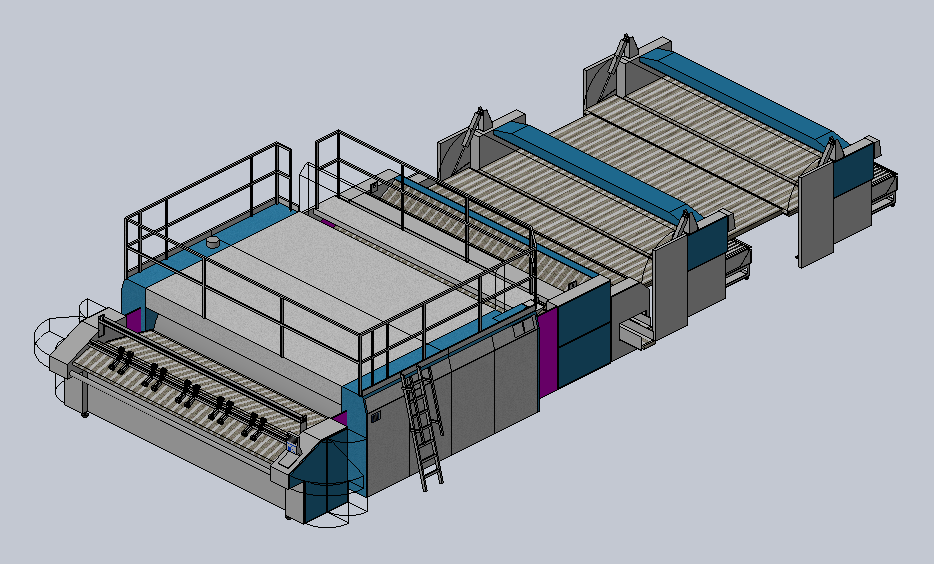

The new ironer line with the SKF small piece sorting system provides a flexible solution to this problem. Batches containing two types of articles of different sizes can be fed at the same time. The machine automatically separates and sorts the items and folds them individually with the highest precision and speed. The automatic sorting avoids errors and reduces personnel costs. Employees do not have to sort the items by size before ironing and can keep a particular customer's laundry together. This means nothing gets in the way of more efficient dispatch.

The SKF small piece sorting system can be connected to a Vectura system for central stack take-off. This ensures correct sorting of the stacks by customer, article or machine for worry-free dispatch.