The more laundry that is washed in professional laundries instead of at home, the better it is for us and for future generations. Laundries continuously optimize their processes in terms of textile care, water consumption, energy efficiency, use of chemicals and waste water pollution. Here, the washing technology from Kannegiesser also enables smaller companies to make huge savings.

Professional washer-extractor technology for the manual washhouse

With the Favorit Vario and the Futura, Kannegiesser has two washer-extractor series in its portfolio for the manually operated washhouse. Both stand in an extraordinary way for washing quality, process optimization, resource saving and process documentation – and these for the entire article spectrum that can be found in laundry operations.

Each batch of laundry is washed with exactly the amount of water and chemicals required for the real batch weight. This ensures high washing quality and the lowest consumption, even when particularly small batches have to be processed. It even takes into account the amount of water that is adsorbed in the textile or that is added via the dosing of chemicals and steam – it couldn't be more precise!

At the same time, JET rinsing ensures low fresh water consumption and fast process times, and thanks to the CareWash perforation, even sensitive textiles are processed extraordinarily gently. The high imbalance tolerance of our washer-extractor technology is particularly important for smaller businesses – after all, the processing of minor batches always leads to very different loading quantities in practice.

The next step: A small batch washer

If the amount of laundry increases, then the PowerTrans Vario JET is the ideal entry-level system for batch washing technology. This opens up new potential for the laundry in terms of automation, logistics and resource savings. A synchronized, continuous flow of laundry is the basis for comprehensive logistical optimization of the entire laundry. Depending on the application and laundry spectrum, the JET-press (with rinsing and extracting in the press) and the JET-centrifuge (with rinsing and extracting in the centrifuge) are available.

Draining the wash liquor before the rinsing process enables savings in water and energy that are only possible with conventional washers if they use additional recovery and treatment systems. The basic principle of the entire PowerTrans Vario series is also ideally suited to small laundries: Due to the save bath separation between the chambers, each batch is washed separately – consistently depending on the program and weight, as in washer-extractors. The unique drum design with ActiveDrop wash action also allows heavily fluctuating loading quantities without reducing consumption or washing quality.

An investment in the future

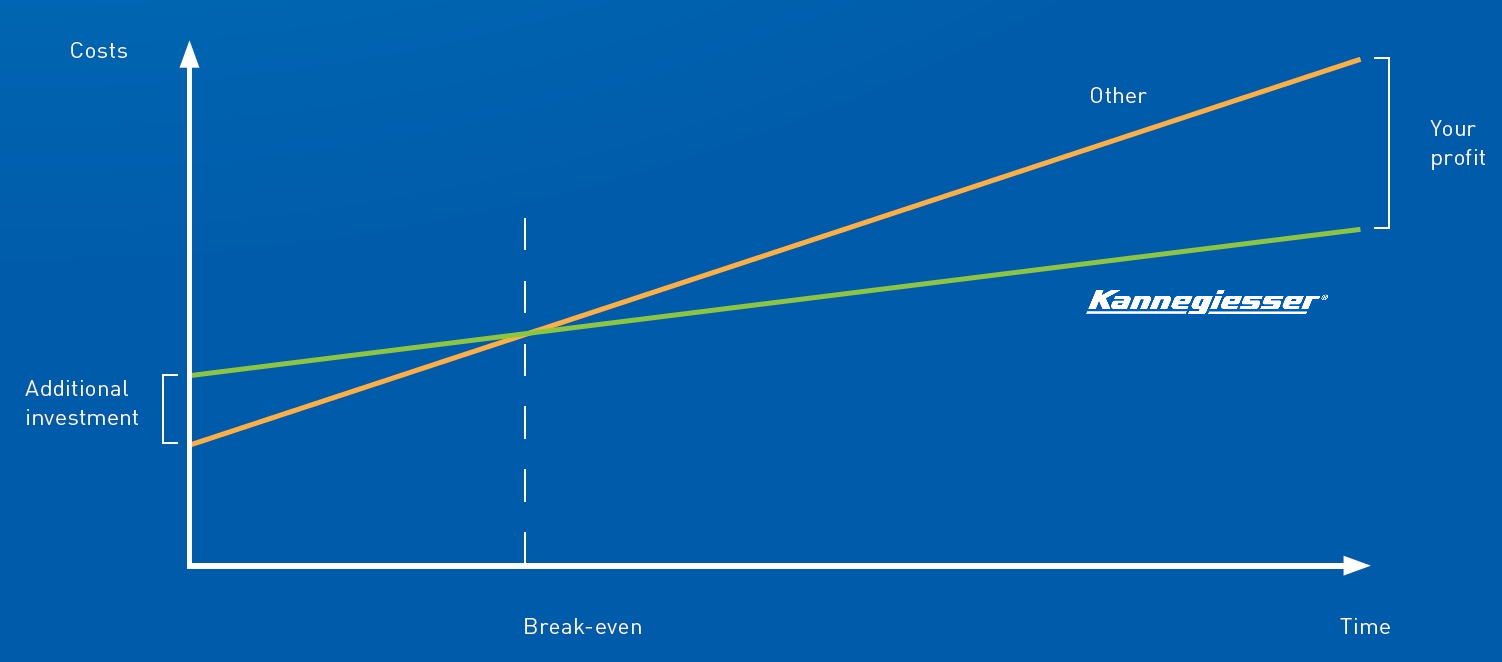

Investing in Kannegiesser washing technology is an investment in the future. For this purpose, always consider the total costs over the entire lifetime of the machine. A lower purchase price often goes hand in hand with higher total costs over the service life. Therefore, a somewhat higher investment often pays off quickly. Less heating energy, lower water and waste water costs, higher reliability and availability, longer textile service life and output reserves not only please the launderer, but also the investor and financial manager of the laundry.