Processing mats - an ergonomic nightmare. Laundry staff is usually only able to handle the large, heavy and bulky mats with a great deal of effort. This challenge also troubled Knut Wetzig, CEO of Textil-Service Mecklenburg GmbH in Parchim. At Kannegiesser, he found the perfect solution in a smart washing system with cascading conveyor belts for optimum ergonomics, an automatic process and outstanding quality.

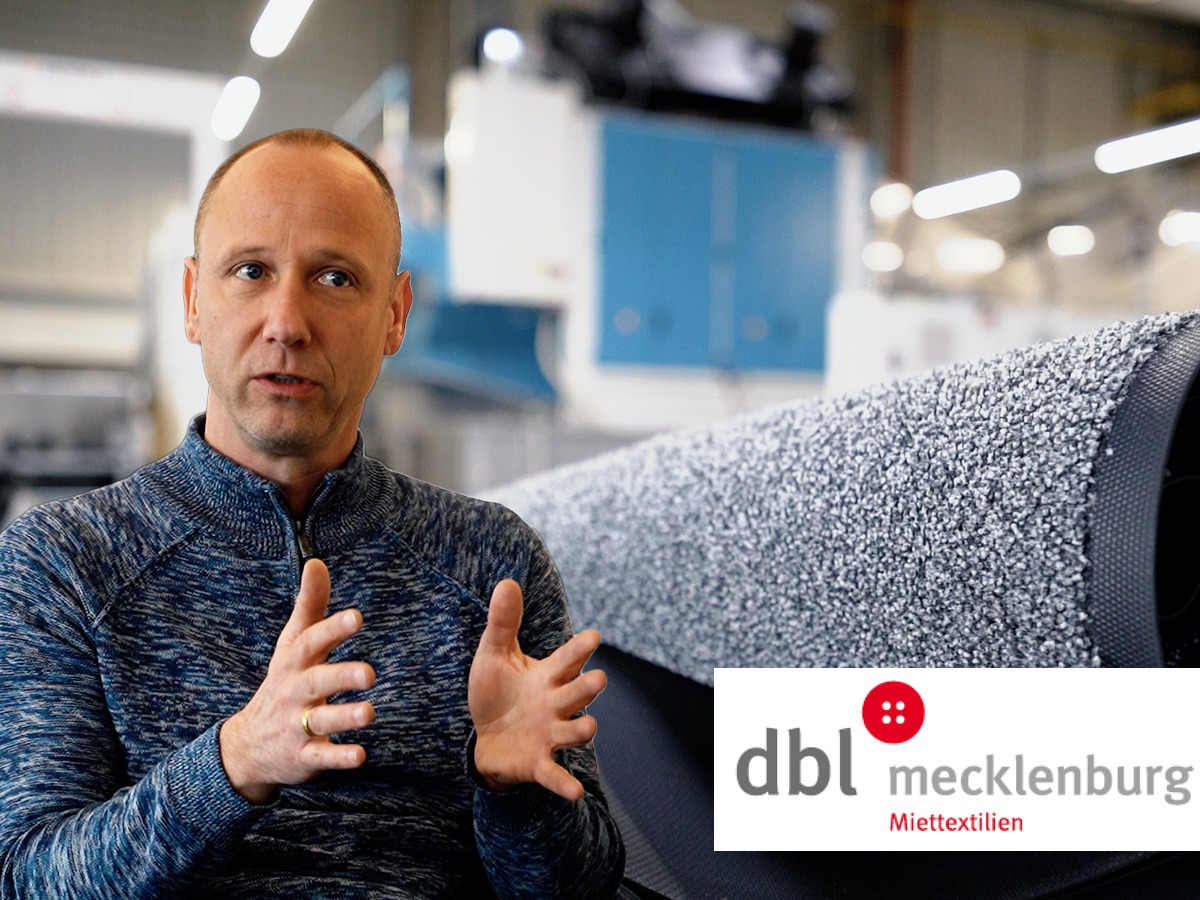

Founded in 1990, Textil-Service Mecklenburg, operating as DBL-Mecklenburg within the DBL business group, now employs around 200 people. Approximately 55,000 people are dressed in workwear processed by the family-run company in northeastern Germany. In addition, DBL Mecklenburg processes about 2 tons of dust control mats per day.

Ergonomics

“We have now installed the new mat washing system as a whole, mainly with the focus on ergonomic relief for our employees”, says Knut Wetzig. It starts with loading the mats into the system.

A dumper automatically feeds the mats, that have been loaded into special containers, into the processing line. Belt conveyors arranged as a cascade transport the mats fully automatically without manual intervention to be washed in the PowerSwing washer extractor and then to be dried in the PowerDry batch dryer. Subsequently, the cascade conveyors also transport the mats to the personnel who roll them up.

“It has the great advantage that the pile of mats, coming out of the dryer, gets disentangled

so that the employees who receive the mats from the last belt, no longer have such a lump of mats to deal with, which they have to pull on with a lot of effort. That makes it easy for them to receive and roll the mats individually”, describes Knut Wetzig.

Quality

The PowerSwing is the perfect solution for the high contamination load of dust control mats. D The Power-Swing achieves the uniquely intensive and gentle wash action with the help of the particularly large drum diameter, the high lifters and thanks to a dynamic drive. At the same time, the integrated ActiveProcessControl system ensures the lowest consumption and shortest process times.

We have dried with the PowerDry before and are doing it again because we are confident about the system," says Knut Wetzig. The PowerDry dries the mats quickly and efficiently without damaging the pile. The optional InfraTouch control detects the item temperature, recognizes the drying progress and can thereby terminate the drying process independently. Each laundry batch is treated individually. Over-drying of the items is reliably avoided, performance and quality increase, and energy consumption is reduced.

Thanks to the cascade conveyors, the mats can cool down after drying and can be rolled up without hesitation. "If the mats are rolled when they are too hot, the rubber memorizes the ripples." According to Knut Wetzig, this leads to rippled mats that don't lay flat. Thanks to Kannegiesser's engineering, this is no longer a problem.

Knut Wetzig, the CEO of DBL Mecklenburg summarizes: “Now we have a process, which is defined, is being followed and results in mats with good quality at the end of the day.”