Process water from the washing processes is valuable - not only because of the costs for water and wastewater treatment, but above all because of the thermal energy contained in the process water and the unused washing chemicals. With an intelligent water management the PowerTrans Vario therefore opens up great savings potential.

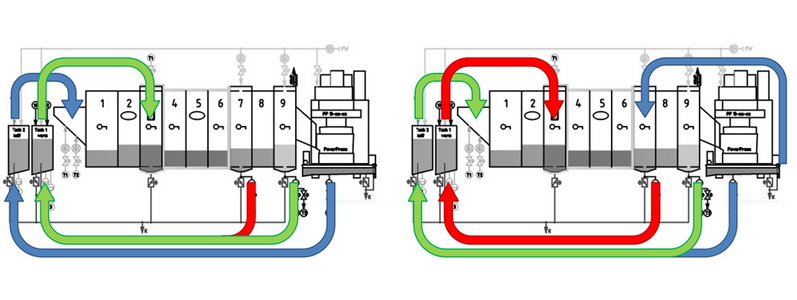

The Eco function

The PowerTrans Vario generally achieves optimized water consumption by reusing the recovered rinsing liquor for the main wash and the press/centrifuge liquor for the prewash. In practice there are different variants of this procedure. The greatest savings can be achieved with the Eco function, in which the liquor form the extraction unit is used directly for pre-rinsing. At the same time, the hot wash liquor is recovered in a separate tank and can be reused undiluted for the main wash.

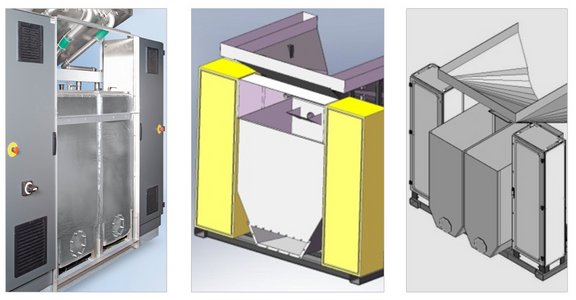

Internal cockpit recovery tanks

Depending on the application, the PowerTrans Vario is equipped with one or two cockpit recovery tanks. The silo shape of the cockpit tanks is also ideal for heavily soiled water and offers the highest usable volume in the smallest footprint. Broadened or elongated versions are optionally available. The tanks are fully insulated as standard and can be equipped with cleaning nozzles.

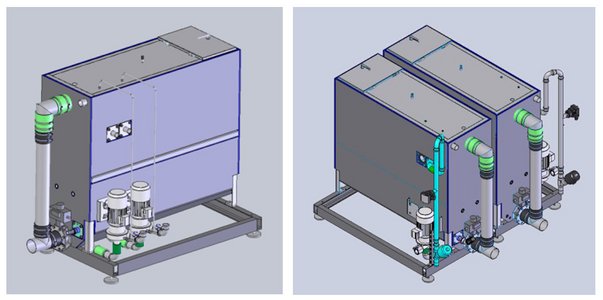

SpecialTank Reservoir STR

The STR provides large storage capacities. Recovered liquor that cannot directly be used in the washing process because of its color is stored in fully insulated tank modules. Whether an STR in-stead of cockpit tanks makes sense or not strongly depends on the size of the machine and on the frequency of color changes on the tunnel.

Storage modules with 2 m³ and 4 m³ volume are available, which can also be combined:

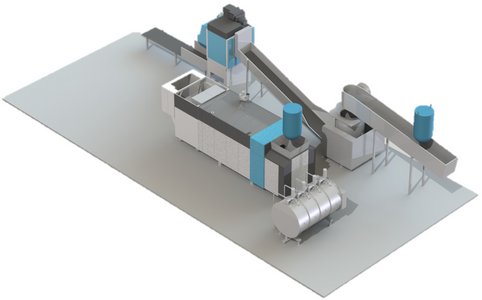

SpecialTankSystem STS

While the STR always belongs to a single PowerTrans, the SpecialTankSystem STS is an independent central system with its own control. Several batch washers and washer extractors can be connected to an STS and optimize their water balance among themselves. For example, several batch washers use the same process water, or excess water from the batch washers is used for heavily soiled laundry on washer extractors.