The principle of a hygienic machine design is to avoid from the ground up any areas in which dirt and microorganisms can settle permanently. This has been consistently implemented in the PowerSpin extraction centrifuge. The PowerSpin has a large inner drum with special perforations and special surface finishing. The unloading occurs smoothly without any auxiliary aid, so without a dirt-prone net or inflatable air bellows – and also without any requirement for either an integrated belt or a more failure-prone pusher. This means that the PowerSpin offers maximum operating safety, reliability and hygiene.

On the safe side!

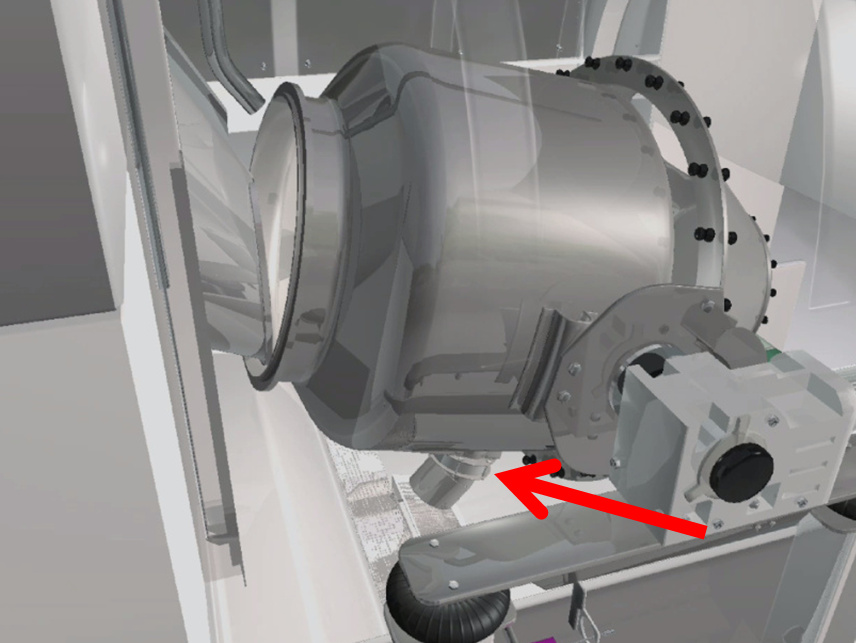

With the optionally available cleaning and disinfection support, even the hard-to-reach areas of the centrifuge drum can be thoroughly cleaned regularly. During this process, the drum is rinsed with a programmable cleaning and disinfecting solution. This solution is active for a configurable time before it is drained off and rinsed out. A closed drain valve on the outer drum of the PowerSpin ensures that the chemicals remain in the drum.

Sequence of the automatic cleaning and disinfection support:

- Loose dirt is rinsed from the bottom tank with fresh water.

- Rinsing the centrifuge drum with a programmable cleaning solution.

- The cleaning solution is drained into the bottom tank and can also act there.

- Cleaning solution is drained to the sewer.

- Chemicals get rinsed out of the drum with fresh water

- Fresh water is pumped from the bottom tank back into the rotating

- Flushing out residual chemicals.

- The fresh water is drained through the bottom tank

- The PowerSpon is ready for the next batch of laundry.

DId you know?

If both the PowerTrans and the PowerSpin are equipped with the respective options "cleaning and disinfection support", then the cleaning process works integrated with both machines. The PowerSpin takes the cleaning fluid from the PowerTrans into the centrifuge drum and lets this chemistry act at a defined speed and drum position for a defined time with the closed drain valve. Then the cleaning liquid is drained through the bottom tank and the drum is rinsed with fresh water.